About Us

Shantou Best Science & Technology Co. Ltd., is a High-Tech enterprise specialized in functional additives/masterbatches for BOPP films, with the ability to provide tailor-made solution to BOPP film manufacturers by combining research and development, manufacture and sales in one company. We also manufacture the additives/masterbatches for cast film, blown film and POF film.

Since the establishment in 2001, our capacity has been over 10,000 tons with the leading-edge equipments, superior technology and the well-found testing equipments, which provides the powerful guarantee for sustainable high quality products. The experienced technical engineers provide you the best solution for masterbatches/additives...

Established in

Covering an area of 27 mu, 10 production lines

Design annual capacity 40000 tons/year

Recommend

For the two-way stretch film enterprises to provide a full range of functional masterbatch additives, but also the production of cast film, blown film, heat shrinkable film with masterbatch additives.

Category

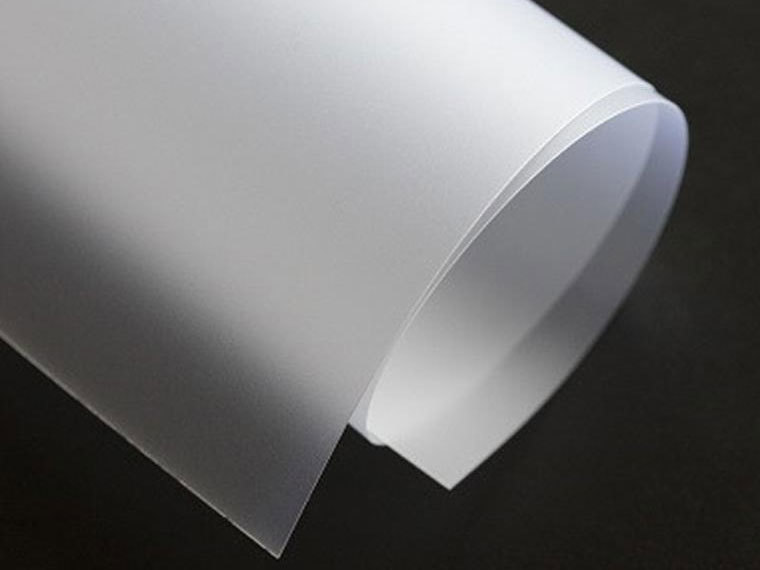

BOPP functional masterbatch refers to the polymer material additives added in the production of functional BOPP film. These additives are the key materials for the specific properties of the film. BOPP functional masterbatch includes but is not limited to matting masterbatch, pearlescent masterbatch, and reinforced masterbatch. They are made by mixing with polypropylene in a certain proportion during the production process to increase the dispersion and uniformity of additives. These masterbatches play an important role in the production of BOPP film. By adding different functional additive masterbatches, films with specific functions can be produced, such as antistatic, smooth, rigid, antireflective, pearlescent, whitening, anti-blocking, synthetic paper effect, anti-fog drop, matting, anti-oxidation, etc.

MoreBOPET functional masterbatch is a special material, mainly used to improve the performance of BOPET film. BOPET, or biaxially oriented polyester film, is a high-performance packaging material widely used in food, medicine, electronics and other product packaging. Functional masterbatch is to improve or increase some specific functions of BOPET film by adding specific additives or reinforcing materials in the BOPET production process. These functions may include increasing the heat distortion temperature, reducing the coefficient of thermal expansion, increasing the barrier properties of plastics, improving transparency and pigment coloration, improving flame retardancy, enhancing dimensional stability, etc.

MoreCPP/ CPE & BLOWN PP/PE Masterbatch

CPP/CPE cast film function masterbatch refers to the functional requirements, with a certain proportion of modified masterbatch, metallocene and other materials, through one or more extruders melt co-extrusion casting, non-or one-way micro-stretching method manufactured by the extrusion film. Cast film is a non-stretching, non-directional cast film produced by melt drooling quenching, which can be made by single-layer drooling or multi-layer co-extrusion casting. CPP (Cast Polypropylene Film) and CPE (Three-Layer Co-Extruded Cast Polyethylene Film) are two common types of cast films, both of which have excellent transparency, gloss, thickness uniformity and other characteristics, and are widely used in food, daily cosmetics, industrial products and other packaging applications.

MoreMasterbatch Corresponding Film Application

Products similar to "industrial MSG", widely used in a variety of functional films

Basic raw materials Functional Additives

Drive the development of domestic basic functional materials

Functional masterbatch

(industrial salt and monosodium glutamate, key and essential)

(industrial salt and monosodium glutamate, key and essential)

Influence and determine downstream film quality and value

Thin film industry hundred billion market

Our advantage

Advanced technology

A high-tech enterprise integrating research, development and production

Perfect equipment

HITACHI SEM, BYK HAZE TESTER, ANGILIENT

Annual output

Over 30,000 tons annually

Experienced Team

Over 25 years stable masterbatch formula. Best had technical engineer with over 20 years experience in BOPP/ BOPET industry

R&D Support

National and provincial laboratories,perfect detection and analysis services

Qualification

National high-tech enterprises, national intellectual property advantage enterprises, through the ISO9001 quality management system certification

Numbers of patents

81 patents Undertake 35 technical innovation projects ofprovincial and civiclevels

Trusted by customers

Recommended and approved by Brueckner on BOPP & BOPET Film Masterbatch

News

2024/04/26

2023/11/30